Question. What is the warehouse? According to some common yet biased opinions, a warehouse is a sort of the black sheep of an enterprise. It is regarded as a place that generates nothing but additional costs, freezes working capital and complicates the work of a business. This is the reason why many executives choose to pay little attention to warehouses and its staff (unless they are similar to Michael Scott from “The Office”, of course). For instance, just 26% of the industry’s CEOs see warehouses and distribution centers as growth-driving assets of their venture. As Mark Wheeler, the CEO of Warehouse Solutions, Motorola Solutions put it: “Warehousing and distribution have not traditionally been the most celebrated functions within leading businesses across manufacturing, retail and wholesale industries”.

However, the domain of modern logistics is on the rise, and new ventures inevitably appear which leads to the growth of their infrastructure. The report by the Bureau of Labor Statistics claims that the number of operating warehouses has increased by 10.4% over the last couple of years – an increase of over 1,600 new warehouses in the U.S alone.

It’s fair to say that describing a warehouse manager’s job as just busy would be an understatement. They have to manage, control, and track inventory as efficiently as possible on a daily basis. And it’s impossible to stress enough how painful the process of management is if a manager is in charge of multiple warehouses when the workload and stress increase tenfold. That’s why a decent warehouse management software is a must-have solution for logistics managers.

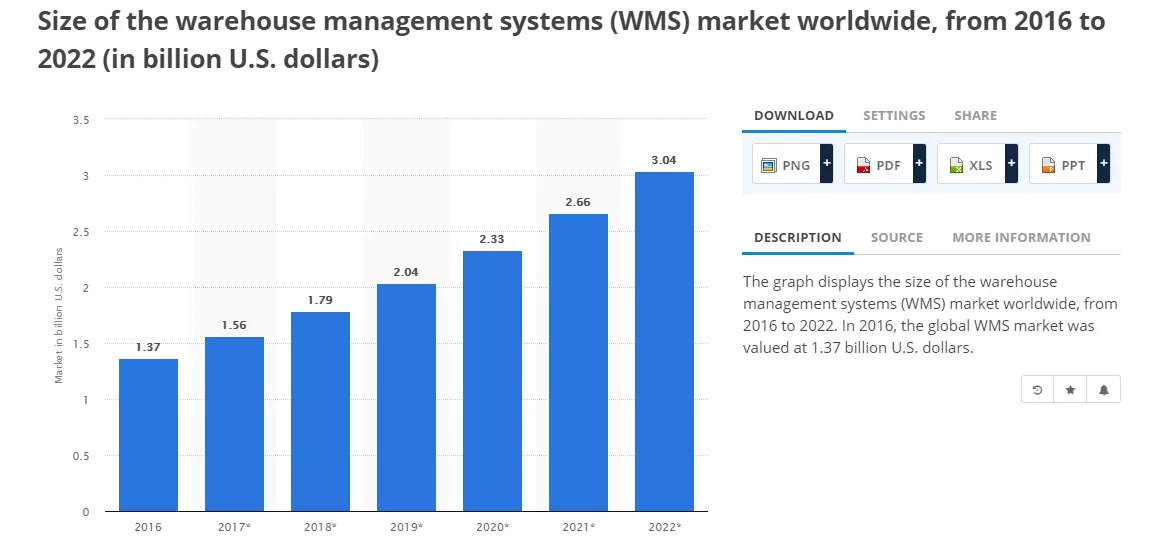

WMS (warehouse management system) is the brain of a modern warehouse, if I may put it this way. The progenitors of modern solutions began to appear in the early 90s, along with the availability of new powerful computer systems. Two and a half decades later, warehouse management programs have been improved and differentiated. Traditionally, such systems consist of two types:

– a customized system developed for a specific client;

– standard equipment.

A properly-made WMS coordinates and synchronizes incoming and outgoing goods flows, internal regulatory operations, personnel work, loading and unloading equipment, robotic equipment and much more.

Automated accounting of goods in the warehouse depends on the following components:

- software is the central part of warehouse automation, which is responsible for the operation algorithms and logic of a WMS system;

- equipment — warehouse automation solutions involve the use of devices such as barcode scanners and printers, data collection terminals, label applicators, and so on;

- an individual project for the organization of warehouse accounting automation developed for each specific enterprise.

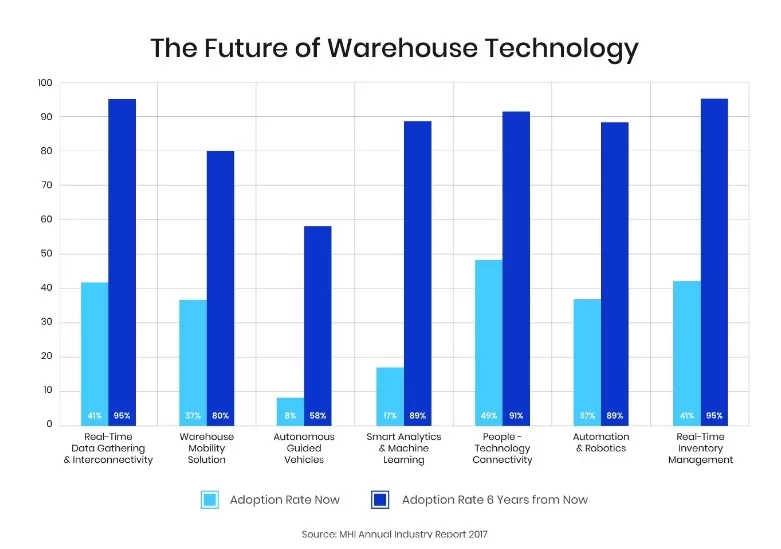

So, despite some level of scepticism, as many as 66% of retailers had plans to make a significant investment in warehouse and inventory management technology in 2018, according to The Motorola Future of Warehousing. Is there a contradiction? Not at all. If you check the report by PeopleVox, you’ll notice that the consequences of human error are seen as the top problem in 46% of all warehouses.

In a nutshell, the advantages of a warehouse management system are:

- the ability to quickly obtain the necessary information about the state of the goods, order or batch – regardless of where in the world you are located;

- ergonomic use of space in the warehouse;

- high speed of all operations (receiving, picking, shipping and writing off the goods);

- systematization of the nomenclature directory, accounting for not only goods but also components, sorting by groups and objects;

- simplicity in working with clients and new partners;

- productivity increase;

- an increase in the throughput of a warehouse;

- reduced administrative costs.

All in all, despite the irrational fear of IT solutions taking jobs off the human, the use of WMS is totally beneficial for staff. It provides a high level of familiarity with modern logistics concepts and increases the overall computer literacy.

How to wisely choose a warehouse management solution

Before start thinking about a warehouse management solution, a number of nuances should be taken into account. First, among all available WMS systems, there are no universal or best ones. Each of the warehouse management solutions is more or less suitable for the workflow of a particular enterprise.

As there are several directions that can be taken, the process of building a technology stack may become a headache. Again – there’s no single route to follow, but it all starts with an understanding of a company’s operational requirements.

If you have few orders to ship daily, there’s no need to invest in an expensive solution. On the contrary, if you have lots of goods to ship, you won’t be happy to rely on outdated technology. When increasing the load on the system, it is important to make sure it corresponds to the pace of business development of the company. So yes, the choice might be really difficult.

However, to facilitate the choice of a WMS system, it is necessary to outline beforehand the goals and problems that automation should solve. If you wish to develop the company in the future, it is necessary to analyze the possibility of scaling up the warehouse management technology. Executives must answer three simple yet vital questions:

– Are business processes within the company optimal?

– What kind of costs should be reduced and by how much?

– What increase in operating profit will make the implementation project a success?

There’s also one particular factor that affects the process of choosing a WMS warehouse automation system – the human factor. Starting from the skill level of warehouse staff and preferences of managers who make financial decisions, each time it is necessary to take into account the influence of subjective opinions, education and training, and, surely, personal qualities.

As for the step-by-step algorithm of actions when choosing a solution, it may be as follows:

- Setting automation goals, determining the size of the budget.

- Providing potential software vendors with the parameters of the warehouse, requesting calculations and proposals.

- Selection of a short list of applicants with the maximum compliance of their proposals with the needs of the warehouse and the capabilities of the customer.

- Formation of a test task for applicants, requests for demo versions, presentations, videos demonstrating how their solutions work.

- Communication with the management of companies that have already established a similar warehouse management system.

- The final comprehensive assessment of projects and the selection of the best ones.

Having such a detailed description of the parameters, managers still need to solve the classical MoB problem (“Make or Buy”): proceed to software development on your own, find a technological partner or purchase a ready-made program.

The answer depends on a number of circumstances, including the degree of elaboration of the management accounting system, the overall architecture of business applications, the availability and stability of the IT resource, and the cost of work.

In the very end, the results of the WSM implementation should be something like this:

- reduction of reserve stock up to 50%;

- reduction in the number of employees by 10-20%;

- reduction of administrative costs by 15-25%;

- increase of space use efficiency by 10-20%;

- reducing the cost of inventory by 75%;

- increase in warehouse capacity by 15-30%.

Final Words

The manufacturer must provide development companies with as much information as possible. After all, the possible degree of programs’ integration plays a significant role in determining the cost and the final positive effect from the introduction of a WMS system.

A bit of history to illustrate the paragraph above. In 2001, HighJump Software, a provider of supply chain management software solutions, signed a contract with Overstock.com which was included in the list of the 40 largest online stores in the United States. At that time, the annual turnover of the client company was approximately $40 million. In the period 2001–2008, it rose to $800 million (i.e., increased 20 times). To ensure such growth, Overstock.com heavily invested in IT tools.

WSM systems have come a long way from elementary solutions for warehouse inventory to full-fledged, powerful systems capable of controlling huge robotic objects. But the need for automation is growing rapidly, and businesses must realize just how efficient their warehouses can be. After all, the customer journey is highly dependant on established warehousing processes.

P.S. If you’ve made this far, chances are you might be interested in developing your own WMS solution. Check out our manufacturing and logistics solutions drop us a line at [email protected]