Nowadays, global spendings on IoT across various business domains don’t cease growing. The International Data Corporation (or simply IDC) predicts that by 2020 this number will grow to $1.2 trillion. The compound annual growth rate (CAGR) will reach 15.6%. Many professionals in the logistics sphere use new resources to improve supply systems and networks, and – eventually – reduce costs. Like it or not, but it’s hard to argue with the fact that digital transformation is the only tried-and-true way to survive and thrive in today’s dynamic new environment.

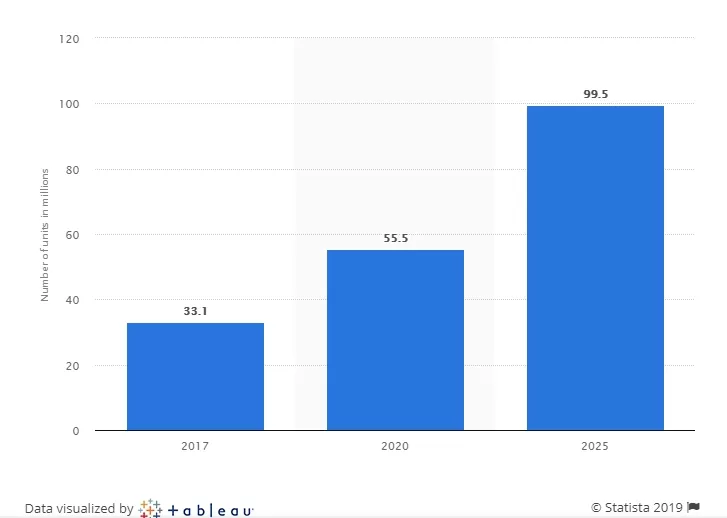

For instance, take a look at the number of Internet of Things (IoT) logistics units in the European Union (EU) in 2017, 2020 and 2025 (in million units).

Security

Distribution centers are a fundamental part of any supply chain. One of the main requirements for a distribution warehouse is the possibility of storing products in a safe way. In modern warehouses, security is provided by alarm sensors and cameras connected to the IoT. However, these devices can only detect a possible theft, and not to prevent it. Well, unless they are equipped with a laser sight machine gun or something.

The process goes as follows: a warehouse owner or tenant installs IoT devices on the site linked to a corresponding application on a smartphone. The application notifies a responsible employee about peculiar movements in the warehouse. By pressing a key on the smartphone, this employee will be able to remotely lock the doors in a matter of seconds and turn on the alarm if it hasn’t turned on already. In some cases, the doors lock themselves without assistance. Then, the data analyst will figure out what’s been wrong on the territory.

But human lives come first. Ensuring the safety of employees is one of the main problems for logistics companies. Do you remember the famous scene in the warehouse in “The Office”? The reality isn’t far from TV shows. For instance, Union Pacific uses IoT to predict equipment failures and reduce the risk of railcars derailment. The company places sensors to monitor the integrity of train wheels. A single crash can lead to delays in delivery and damage to the goods resulting in consequent losses up to $40 million – the compensation for violated deadlines and poor-quality service. Following this model, loaders can alert employees of a defect before an incident. Thus, the risk of accidents is significantly reduced.

Optimization

IoT allows you to have a holistic view of the stock: from temperature, the amount of inventory to equipment performance. Based on this data, companies can analyze overall performance and undertake maneuvers to increase safety and productivity. It’s fair to say that at the core of logistics stands an increased operational efficiency. This way, IoT technologies improve the overall performance of an enterprise.

Tracking

The tracking of goods from the moment of purchase to delivery is a crucial factor for customers. Traditional monitoring consists of scanning the item between delivery points. RFID tags make tracking way easier: they are connected to the cloud and send location data more often in comparison with scanning. Researchers at Auburn University found that 96% of retailers who deliver goods to their homes plan to use RFID technology. RFID tags can also be used in stock to track inventory and reduce unnecessary costs. Inventory levels are around 65% accurate while using RFID is 95% or more.

Delivery

GPS and location data from RFID tags simplify the process of tracking the way goods are delivered. The use of historical data improves logistic operations, and big data reveals the most efficient couriers, truckers, delivery routes, etc. If the employees who are responsible for delivery show poor results, it’s time for them to attend additional training.

But what value does IoT bring for consumers?

Transparency

When making a purchase, consumers appreciate the reliability of a seller. The accurate tracking of information provides customers with confidence in the service and eliminates the need for call center operators.

And it’s something that customers appreciate in monetary terms. According to the American Express survey, Americans feel okay to reward companies that provide customer service just right. The consumers from the USA claim that they would pay an additional 17% to a business that delivers decent service, a raise from 14% back in 2014. By the way, millennials are the ones who are eager to spend the most for great care (21% additional).

Efficiency and simplicity

For example, Istock sensors track the location of each batch via GPS and make sure that both temperature and humidity are okay. It is crucial when it comes to perishable foods. According to the Institution of Mechanical Engineers, 30% of all products with a limited shelf life never reach the final consumer.

…and (predictably) the blockchain

The modern supply chain management is associated with various problems, starting with illegal actions and ending with concerns for the state of the product. That is why transport companies and their customers want to track the product life cycle – from the origin of the goods to their transportation into the hands of the client.

Although the blockchain technology can solve the number of IoT security problems, it can also be of great benefit to supply chains. By going hand in hand, they can satisfy the need for security, transparency, and traceability.

Cases of use

Rogue Ale, based in Newport, Oregon, implements effective tools for tracking supply chain and transporting perishable goods. Rogue produces hops for the process of brewing fresh beer. Hops are not dried in the field but sent for immediate use in breweries. It is necessary to deliver the raw materials within 12 hours, otherwise, the beer will be (as they say) “close to water”. For the preservation of raw materials, Rogue uses sensors that collect data on the temperature and humidity on the way to the brewery.

The startups Flexe (the US) and Stowga (the UK) have created applications and cloud platforms that allow warehouse owners to rent spare capacity, and customers to rent them on demand, depending on the required intervals (from several days to several weeks). Organizations will be able to manage warehouses as a national or international network of small objects, the areas of which will change on demand. Enterprises no longer need to use a huge amount of storage capacity that may be empty. This situation is especially urgent for seasonal businesses. With the help of new platforms on demand, the seemingly unused space will later become a profitable commercial asset.

Let’s take a look at DHL Supply Chain, a branch of Deutsche Post DHL whose main business lies in providing contract logistics services through the entire supply chain. The company uses the so-called Narrowband Internet of Things app (NB-IoT) developed in cooperation with Huawei Technologies. The application makes easier the management of the yard for inbound-to-manufacturing logistics businesses which brings improvements in inbound processing time at the site.

The solution works via a high-speed wireless connection, so the company is able to gather dock availability data in real-time automatically. At the same time, NB-IoT provides visibility to both dispatchers and truck drivers. Besides, it saves the waiting time for drivers up to 40 minutes, which, consequently, reduces the risks of manufacturing delays as materials arrive on time and resources are optimised appropriately.

To sum up

The time when it was enough to move the goods from point A to point B, has passed long ago. Due to the high competition, clients focus on businesses which meet their needs and expectations in fuller measure.

Currently, the priority tasks of logistics companies consist of ensuring the “just in time” delivery, transparency of the supply chain/transportation cycle and quality of services. The success of any logistics company lies in efficient inventory management and warehousing, automating internal business processes, fast delivery and ensuring safe storage of goods.

So this is why it’s high time to implement the principles of 6 R:

- moving the right product;

- in the right quantity and condition;

- at the right time;

- at the right price;

- in the right place;

- to the right customer;

Since the task is very complex, the need to use innovative solutions to achieve business goals is more than vital.